Most of the heavy lifting in woodshops today is done with power tools but there are many situations where hand tools can get the job done just as well or even better than power tools. Some woodworkers even rely on hand tools exclusively. Roy Underhill of Woodwright’s Shop fame, comes to mind. The eco-appeal of […]

Bill Kovalick

As woodworkers, we use wood to build beautiful furniture and other objects. But wood does have a dark side: it can be harmful to our health. Trees contain toxins in the bark, fruit, sap, wood, and foliage but for the majority of woodworkers, exposure to the wood and, in particular, wood dust is the primary […]

Wood Dust Health Hazards

Potential Hazards Exposure to wood dust has long been associated with a variety of adverse health effects, including dermatitis, allergic respiratory effects, mucosal and nonallergic respiratory effects, and cancer. Contact with the irritant compounds in wood sap can cause dermatitis and other allergic reactions. The respiratory effects of wood dust exposure include asthma, hypersensitivity pneumonitis, […]

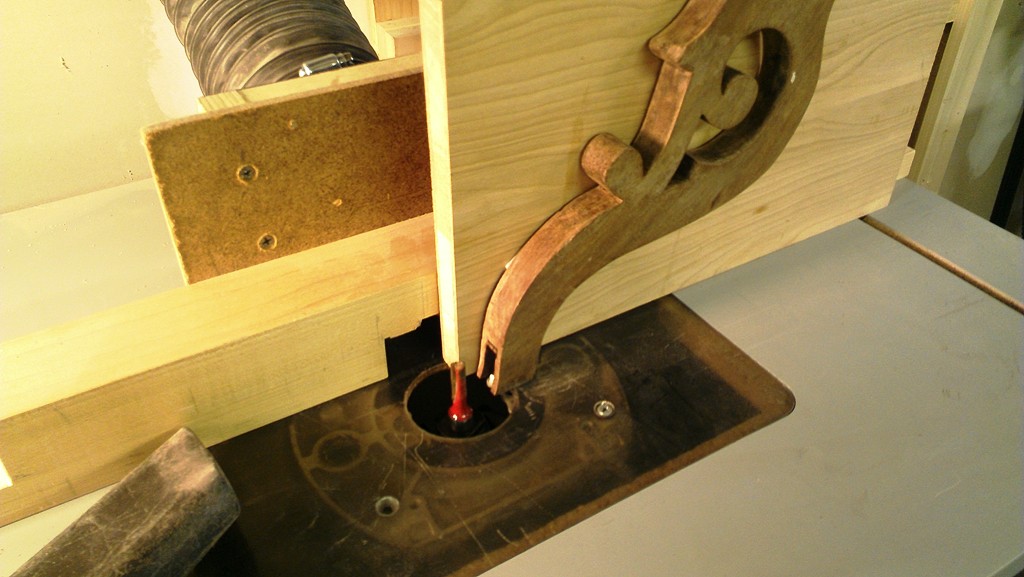

Wood Dust Control for Individual Machines

Every woodworker is faced with this dilemma eventually: what to do with all those off cuts and other wood scraps that are left over from your projects? As an eco-woodworker, you don’t want to just dump the scraps out. But you have to do something because those wood scraps multiply like rabbits and will overrun […]

Ways to Reduce and Recycle Wood Scraps

Instead of throwing out sawdust, wood chips, and shavings that are produced in your woodshop, there are a number of uses for these materials in and around your home and garden. Here are a few ideas. Sawdust Mulch Sawdust can be used as an organic mulch that is very effective at controlling weeds, insulating soil, […]

Recycling Sawdust, Wood Chips, and Shavings

2

2 While building some birdhouses that relied heavily on glue joints to keep the structure intact, I decided to try out Titebond III wood glue. This glue is advertised as being more waterproof than Titebond II, a popular glue for exterior projects that is designated as “water resistant” by the manufacturer, Franklin International. Comparing the labels […]

How Waterproof is TiteBond III?

While restoring an antique parlor table, I ran into a situation in which a couple of the tenons holding the leg assembly together split during disassembly. I tried being careful – I brushed a liberal amount of denatured alcohol on the joint to soften up the old hide glue followed by gentle tapping with a […]

Repairing a Broken Tenon

Although it may look like frost, the white in the photo below is actually an example of shellac blushing. Blushing is caused by moisture that gets trapped in the finish when the top layer of the finish dries before the moisture has a chance to escape. It typically occurs when the humidity is high or […]

Shellac Blushing

1

1 Two of the most commonly used power sanders for woodworking purposes are the sheet sander and the random orbital sander. While either of these tools can be used for many of the same basic sanding tasks, there are some fundamental design differences between them and situations where one is more appropriate than the other. If […]

Sheet Sander Versus Random Orbital Sander

After discovering an old dilapidated Singer sewing machine in the upstairs storage area of my dad’s garage, I decided to “repurpose” it as a table. The original wooden work surface of the 100+ year old machine was badly warped and discolored due to water damage so I made an executive decision to replace it with […]

Scalloped Corners

If you cut enough wood, you’ll eventually encounter situations where the saw blade is burning the wood. This usually happens with ripping operations but can also happen with crosscuts. If the burning is really pronounced, it may be accompanied by smoking and a noticeable increase in feed pressure. Although there are a number of causes […]

How to Prevent Saw Blade Burning

This chart compares sandpaper grits using three different grading systems: 1) Coated Abrasives manufacturer’s Institute (CAMI), 2) Federation of European Producers Association (FEPA), and 3) the “0” or “ought” grade system. CAMI and FEPA are the two most common grading systems in use today. CAMI is used primarily in North America whereas FEPA is used […]

Sandpaper Grit Chart

Sanding is not the most pleasant woodworking task but it goes a lot smoother (pun intended) if you have a system in place for choosing sandpaper grits. That is: what grit to start with, what grit to end with, and what grits to use in between. This process is sometimes referred to as a sanding […]

Going Through the Grits

I’ve accumulated several different types of sanding tools over the years, some of which are used much more frequently than others but all have their place. My sanding arsenal includes hand-held tools: a sheet sander, a random orbital sander, a belt sander, sanding blocks, a detail sander, and a cabinet scraper, as well as stationary tools: […]

An Assortment of Wood Sanding Tools

Sanding isn’t fundamentally difficult but its still easy to make mistakes. This is often due to carelessness, such as over sanding the edges of a table top, but can also be due to procedural screw-ups such as not using the right tool or type of sandpaper for the job. Or sanding against the grain. Laziness […]

Common Sanding Mistakes

1

1 One day in the woodshop… I was applying a finish to a newly constructed coffee table and I activated my fume control system. This involves opening one of the windows and turning on a fan that is positioned in front of the window to blow fume-laden air outside. It actually works fairly well at clearing […]

Removing Rust from A Jointer Bed

1

1 If you’re fond of all your fingers, a good way to help keep them is by using a push stick or push block. This is especially pertinent when milling small pieces on the table saw and jointer but also applies to the router table, shaper, and band saw. A push stick keeps your precious body […]

Push Sticks and Push Blocks – You Can Never Have ...

Here’s a method for routing evenly spaced parallel grooves on a router table that is fast, accurate, and doesn’t require moving the router fence for each pass. The trick is to create a set of equal width spacers, whose width equals the spacing between grooves. After each routing pass, a spacer is removed to position […]